EIT RawMaterials: SUPERSMART innovation project kicks off

SUPERSMART to scale-up printed electronics and recyclable smart materials

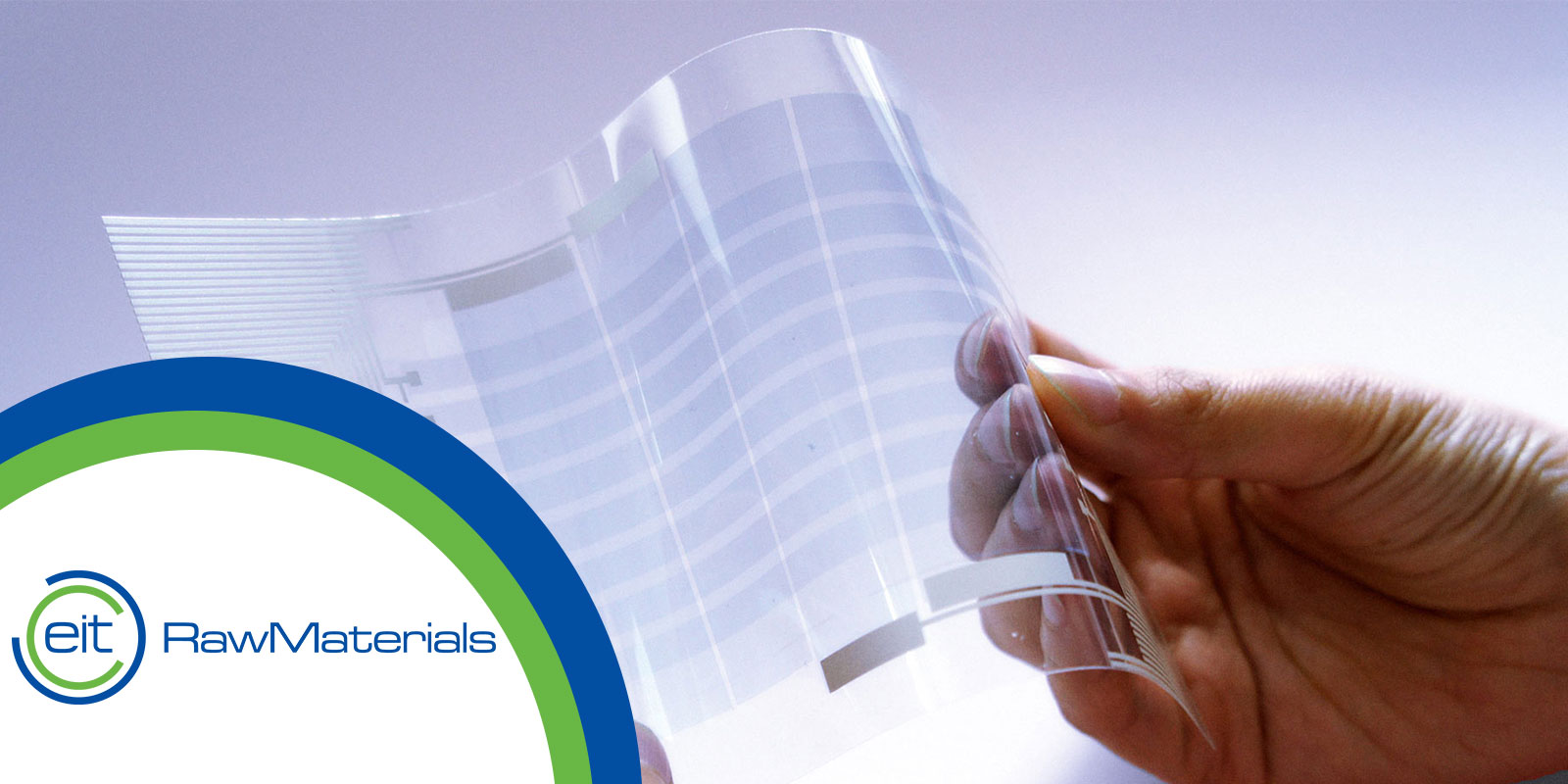

With the Internet of Things trend there is a rising demand for intelligent product labeling including packaging for electronics and health care industry. Paper-based electronics industry "papertronics" is set to meet large market demands for flexible and interactive devices, not only because of the technological breakthrough but also because paper and cardboard are the most recycled products in Europe.

Currently embedding sensors technologies with minimal environmental impact remains challenging. An elegant solution consists of using an organic and hybrid organic-inorganic materials to replace metals. It requires extensive know-how to design and synthesize such materials yet making functional devices is equally challenging.

The modern printing industry requires inks to be compatible with certain processability and productivity standards. Likewise, the paper substrate must be adapted while retaining its appealing texture for the customers. And non-negligibly, to achieve functional papertronic devices, several microscopic layers of materials may have to be printed side by side or on top of each other.

Enabling the emergence of printed electronics products

In this EIT RawMaterials innovation project, the partners will scale-up the production of a set of materials of organic, hybrid or inorganic nature, that have been developed over the last years. Those will then be formulated into inks that, together with newly upscaled specialty papers, shall be commercialized. But before, the latter shall be validated in an industrial environment. There are many printing techniques – flexography, inkjet or roll-to-roll. Since an important benefit of printing lies in low-cost volume-fabrication, this validation phase shall fine-tune the properties of the inks and papers towards maximal productivity and reproducibility.

Once their properties will be optimised, the consortium will design and prepare demonstrators to promote the technology to the intended markets. The total packaging market represents a turnover of about USD 450 billion, ten percent of which could be rapidly conquered with smart technologies. The consortium will promote pressure and shock detection tags that will evidence shock, fall or even vibrations suffered by manufacturing goods during transportation. Likewise, smart and anti-counterfeit labels aim at introducing new functionalities to luxury and pharmaceutical packaging or to medical devices.

The members of the SUPERSMART innovation project consortium are:

- Arkema France (Lead Partner)

- Arjowiggins Rives

- Coatema Coating Machinery

- French Alternative Energies and Atomic Energy Commission

- Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V.

- Joanneum Research

- Luquet & Duranton

- Technical Research Centre of Finland Ltd. VTT

- New University of Lisbon – Faculty of Sciences and Technology

- University of Bourdeaux

Catch up with the latest news from the EIT Community in the Newsroom.

Subscribe to the EIT Newsletter to get the best of the EIT Community's news in your inbox once each month.

Share this page

Share this page