Implementing RTLS (Real-Time Location System) through EIT Manufacturing

With the help of EIT Manufacturing, Komete signed a business agreement with New York-based industrial group Wabtec to use Komete's technology in Wabtec's Italian production plant.

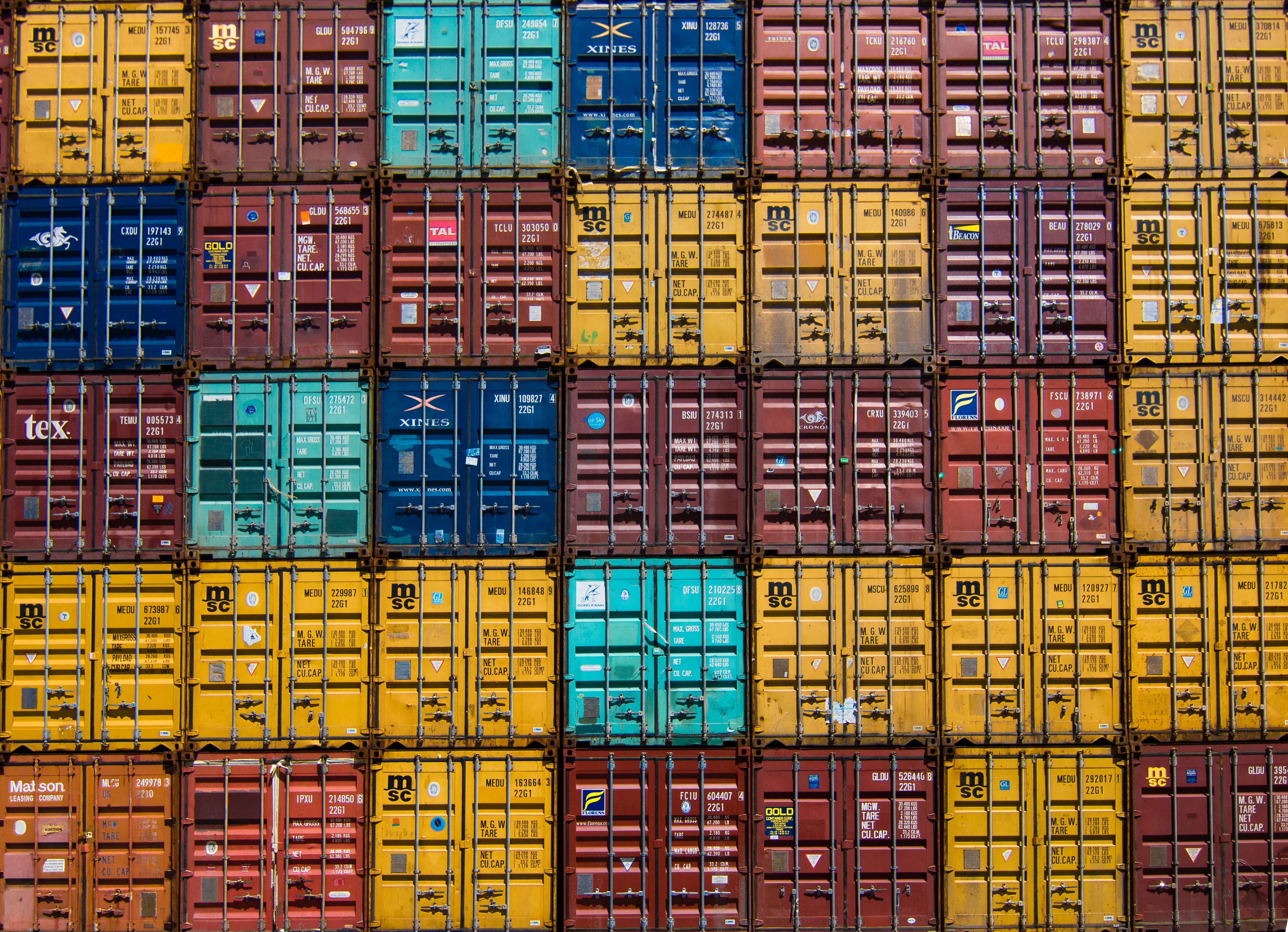

Tracking the movements of orders, semi-finished products or other goods within a bustling factory environment poses a significant challenge. The complexity of production processes often makes it difficult for operators to keep tabs on these items. Traditional tracking methods fall short, leading to delays, inefficiencies, and a limited understanding of the production flow.

Komete‘s plug-and-play IoT technology offers, through the use of small sensors, a real-time and user-friendly approach to monitor these items, bringing enhanced visibility and efficiency to factory logistics.

A chance meeting turned opportunity

By answering an invitation to a Technology Deep Dive Event (demistyfication event) organised by EIT Manufacturing and Mesap, Komete seized a valuable opportunity to connect with Wabtec Corporation. This event served as the ideal platform for both companies to engage in a more advanced and substantive discussion.

EIT Manufacturing’s efforts in connecting companies and start-ups have proven to be instrumental in accelerating the development of Komete. The well-designed Tech Deep Dives events provide start-ups with valuable opportunities to meet potential corporate clients, such as the successful pilot initiated with Wabtec Corporation.

Francesco Gaetarelli, CEO & Co-founder of Komete

From words to deeds

Wabtec Corporation, a major industrial group based in New York, is renowned for manufacturing products for locomotives, freight cars, and passenger transport vehicles. That includes brake subsystems, electronic train control equipment, coupling systems, door control, and air conditioning systems.

Following EIT Manufacturing’s event, this company implemented Komete’s technology in its production plant in Piossasco, Italy, and observed significant improvements in its day-to-day operations.

Before Komete’s integration, line operators relied on manual declarations of product progress in dedicated production cells. This approach lacked accuracy and real-time insights into time spent on different production sub-stages, including rework and deviations from standards. The lack of objective data hindered production managers in making impartial decisions for operational optimisation. Furthermore, the need for manual input added to the workload of line operators, consuming valuable time.

The integration of Komete’s technology significantly reduced production times thanks to the collection of meticulous data to rationalise operations. Now, the Italian production plant has complete and objective traceability of the production flow for each product, reducing the time operators spend updating order status and allowing them to concentrate on value-added activities.

The Komete solution is transforming our operations by providing accurate, real-time data, leading to streamlined operations and more efficient production processes. It allows us to make informed decisions that have had a positive impact on our productivity and efficiency.

Matteo Griva, Process Engineer at Wabtec Corporation

Future developments are promising

The parties are planning to use Komete’s asset tag to automatically collect information on the number of cycles that test equipment in climate cells undergoes. This improvement will not only reduce maintenance costs, but also improve the quality of information about the equipment and reduce the time operators spend collecting this data.

Share this page

Share this page